Problem:

In deep hole drilling, coolant must be pumped to the end of the drill in order to cool the bit, flush the chips, reduce deflection of the tool and maintain tolerances. The recycled coolant contains many particles from the drilling process. Filtering the coolant sufficiently for most other centrifugal, screw or piston pumps can be expensive and cumbersome.

Solution:

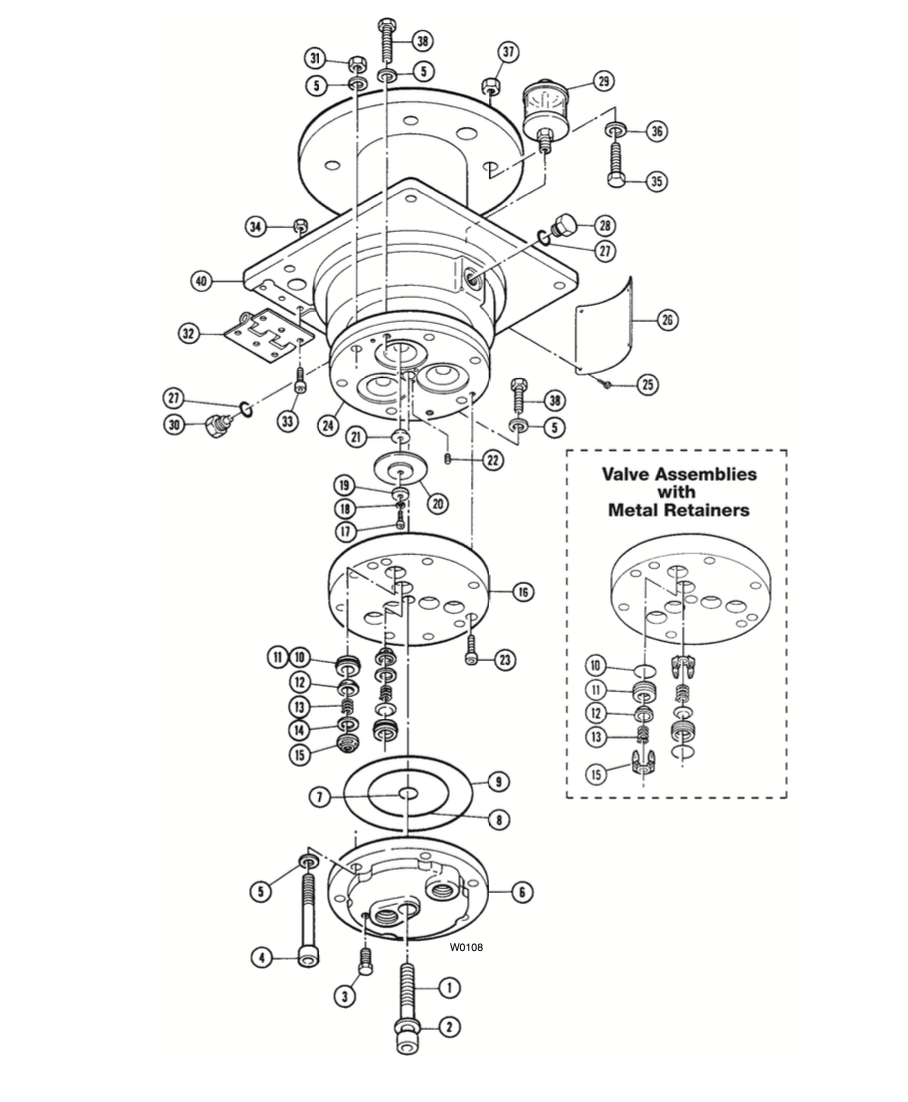

Hydra-Cell coolant pumps

Problem:

Today, most lathes can greatly increase the metal removal rate with high pressure coolant. High pressure coolant reduces thermal shock and the premature tool failure that comes from it. The vapor barrier which forms when coolant boils from the heat generated from the tool and the work piece, can be penetrated with high pressure. The coolant used in these high pressure applications can be recycled, however, most conventional positive displacement high pressure coolant pumps require very clean fluids, thus requiring expensive and cumbersome filtration.

Solution:

Hydra-Cell coolant pumps can handle dirty, recycled coolant!

Click here to see: Instruction_Service_Manual

Click here to see: G12-Datasheet

Contact us by sending a message to:

AT Fluids at Applicazioni Tecniche Srl, Via Piaggio c/o Parco Paglia - Lotto B2, 66100 Chieti CH

Telephone : +39 0871 55 10 20

Whatsapp : +39 340 193 4855